Leading Wahser Manufacturer & Exporter

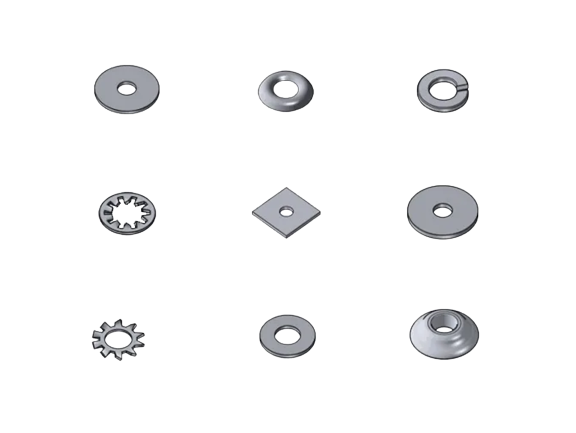

Washers are an essential part of the fasteners' family. They are primarily used to distribute the load evenly on the bearing surface and ensure that they are no dimensional slippage between the different components being fastened. Washers are also used to ensure that the structure being built is resistant to small movements and continuous vibrations. This makes them almost indispensable while constructing anything.

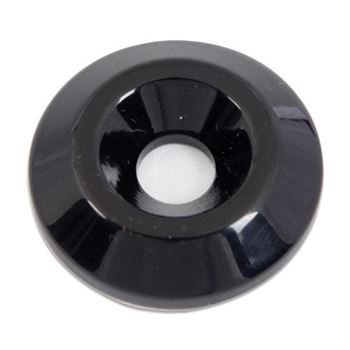

At Standard Exports, we manufacture & export several types of washers in multiple dimensional standards and material of construction. To name a few of the washers we manufacture, we have spring washer/helical lock washers, spherical washer with conical seat, plain/punched/plate washers, belleville washers, HSFG washers, disc springs, taper washer, wedge lock washer, wave washers for ball bearings, serrated lock washers - internal and external, rib washers, shims and support rings. Reach out to us at info@standardexports.co.in to know more about our products and services.

Standard Exports' Washers Specifications

| Washer Size | Size : M12 TO M100 | 1/2" TO 4" | Custom Sizes |

|---|---|

| Measurement | UNF, BSW, BSF, METRIC, UNC, or as required |

| Standard of Washers | DIN 934, DIN 931, DIN 970, DIN 933, JIS standards, ISO 4033, ISO 4032, ASME B18.5, ANSI B 28.2.4 1M, ANSI B 18.2.4 2M |

| Material | MS , En Series, Copper, Brass , Aluminium, Stainless Steel |

| Surface Coating | PTFE Coated Washers / Phosphate Coating / Teflon Coating / Zinc Coating / Hot Dipped Galvanizing Coating / Cadmium Coating / Xylon Coating |

| Washers finishing | Self-Color, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating, Dacroment, nickel-plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide, |

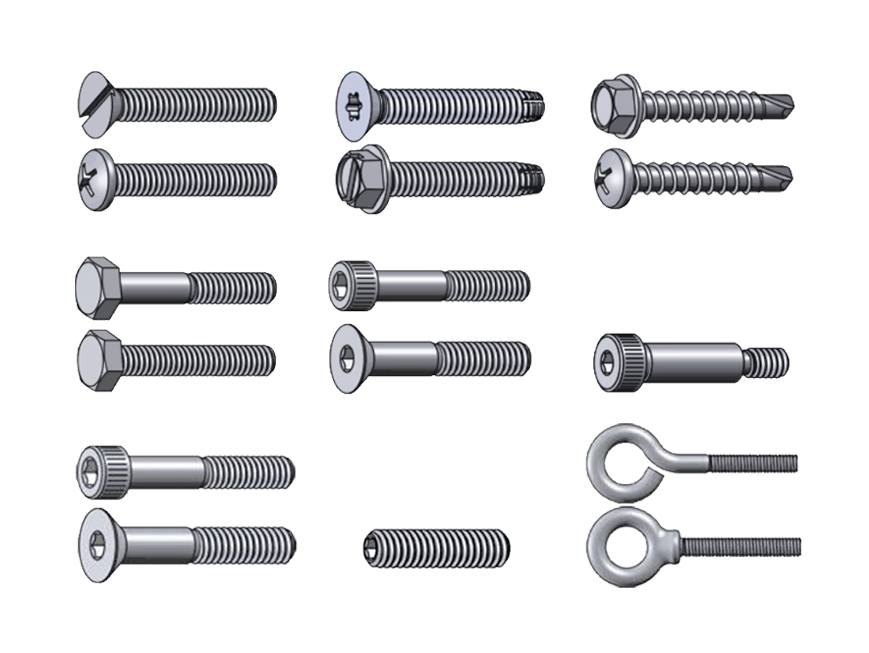

Bolts

Bolts

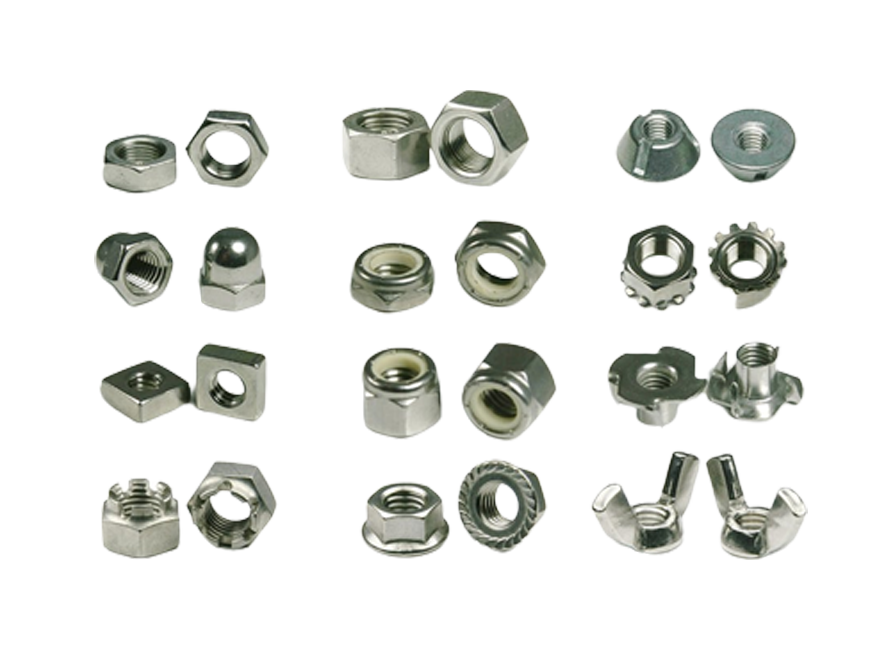

Nuts

Nuts

Washers

Washers